Add to Cart

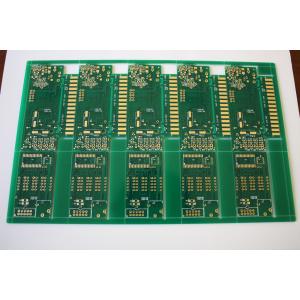

Impedance Control PCB OEM Service Fully Inspected ROHS Comply multilayer pcb manufacturing

Key Specifications/Special Features :

| Base Material : | FR4TG180 |

| Board Thickness : | 0.8 mm |

| Layers : | 2-20 layers |

| Copper thickness : | 2 OZ In all layer |

| Surface Finish : | ENIG |

| Tolerance : | +/-0.01mm |

| Impedance : | 100Ohm |

| Min. Hole Size : | 0.20mm |

| Min. Line Width : | 0.1mm/4mil |

| Min. Line Spacing : | 4/4mil(0.1/0.1mm) |

| Capacity of Production : | 50000Sq.m/month |

| Certificate: | Certificate: |

| Company type: | Manufacturer/ Factory |

Quality assurance :

Every production process has a special person to test to ensure quality, AOI, E-testing, Flying Probe Test.

Have professional engineers to check the quality

All products have passed CE, FCC, ROHS and other certifications

Technology Capability:

| Item | Technical Parameters |

| Layers | 1-28 Layers |

| Inner Layer Min Trace/Space | 4/4 mil |

| Out Layer Min Trace,Space | 4/4 mil |

| Inner Layer Max Copper | 4 OZ |

| Out Layer Max Copper | 4 OZ |

| Inner Layer Min Copper | 1/3 oz |

| Out Layer Min Copper | 1/3 oz |

| Min hole size | 0.15 mm |

| Max.board thickness | 6 mm |

| Min.board thickness | 0.2mm |

| Max.board size | 680*1200 mm |

| PTH Tolerance | +/-0.075mm |

| NPTH Tolerance | +/-0.05mm |

| Countersink Tolerance | +/-0.15mm |

| Board Thickness Tolerance | +/-10% |

| Min BGA | 7mil |

| Min SMT | 7*10 mil |

| Solder mask bridge | 4 mil |

| Solder mask color | White,black,blue,green,yellow,red,etc |

| Legend color | White,black,yellow,gray,etc |

| Surface finish | HAL,OSP, Immersion Ni/Au ,Imm silver/SN,ENIG |

| Board materials | FR-4;high TG;HighCTI; halogen free; Aluminum Bsed PCB,high frequency(rogers,isola),copper -base PCB |

| Impedance control | +/-10% |

| Bow and twist | ≤0.5 |

Application:

Widely used in stage, Industrila control,computer,consuming electronics,security,automotive,power electronics,medical,telecom etc.

Lead Time :

| Lead Time | 2 /L | 4 /L | 6/ L | 8/ L |

| Sample Order | 3-5days | 6-8days | 10-12days | 12-14days |

| Mass Production | 7-9days | 8-10days | 12-15days | 15-18days |

FAQ :

1. How do ACCPCB ensure quality?

Our high quality standard is achieved with the following.

1.1 The process is strictly controlled under ISO 9001:2008 standards.

1.2 Extensive use of software in managing the production process

1.3 State-of-art testing equipments and tools. E.g. Flying Probe,e-Testing, X-ray Inspection, AOI (Automated Optical Inspector) .

1.4.Dedicated quality assurance team with failure case analysis process

2. What kinds of boards can ACCPCB process?

Common FR4, high-TG and halogen-free boards, Rogers, Arlon, Telfon, aluminum/copper-based boards, PI, etc.

3. What data are needed for PCB production?

PCB Gerber files with RS-274-X format.

4. What’s the typical process flow for multi-layer PCB?

Material cutting → Inner dry film → inner etching → Inner AOI → Multi-bond→ Layer stack up Pressing → Drilling → PTH → Panel Plating → Outer Dry Film → Pattern Plating → Outer etching → Outer AOI → Solder Mask → Component Mark → Surface finish → Routing → E/T → Visual Inspection.

5. How many types of surface finish ACCPCB can do?

the leader has the full series of surface finish, such as: ENIG, OSP, LF-HASL, gold plating (soft/hard), immersion silver, Tin, silver plating, immersion tin plating, carbon ink and etc. .. OSP, ENIG, OSP + ENIG commonly used on the HDI, we usually recommend that you use a client or OSP OSP + ENIG if BGA PAD size less than 0.3 mm.

6. What are the main factors which will affect the price of PCB?

Material;

Surface finish;

Board thickness, Copper thickness;

Technology difficulty;

Different quality criteria;

PCB characteristics;

Payment terms;